|

|

ATSF Ce-1 Waycar 999131

Centralia Car Shops makes a terrific Santa Fe waycar, but there are several ways to improve it.

Starting from a pre-decorated ready-to-run model, I installed red LED end warning lights and

a basic DCC decoder to control them. I also replaced and added several details, along with

weathering to create a more accurate and realistic model. An indispensible resource for this

project was the all-color book "Santa Fe Waycars" by Stephen Priest (out of print).

Centralia Car Shops makes a terrific Santa Fe waycar, but there are several ways to improve it.

Starting from a pre-decorated ready-to-run model, I installed red LED end warning lights and

a basic DCC decoder to control them. I also replaced and added several details, along with

weathering to create a more accurate and realistic model. An indispensible resource for this

project was the all-color book "Santa Fe Waycars" by Stephen Priest (out of print).

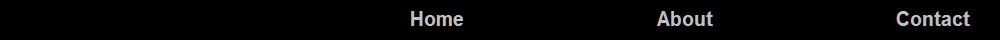

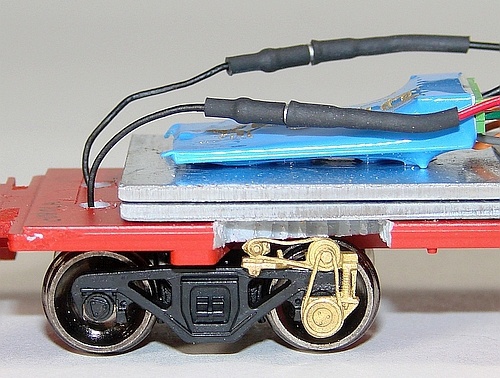

I replaced the stock trucks with Athearn 4593 modern caboose trucks.

These have power pickups, to which I soldered small pins in case

I ever need to remove the trucks. I built two wires with mating

receptacles for connection to the DCC decoder inside the car.

These have power pickups, to which I soldered small pins in case

I ever need to remove the trucks. I built two wires with mating

receptacles for connection to the DCC decoder inside the car.

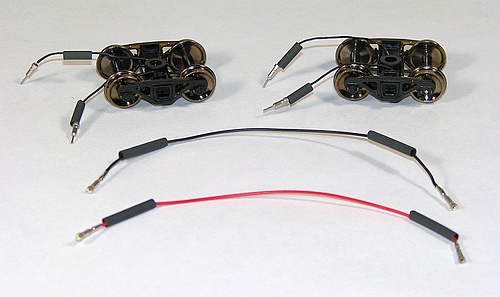

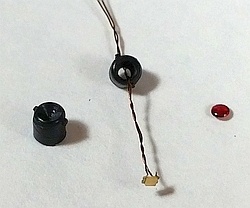

I hand-soldered tiny transformer

wire to Surface-mount style red

LEDs (0603 size). The ruler

reveals the minute scale of this

solder work.

reveals the minute scale of this

solder work.

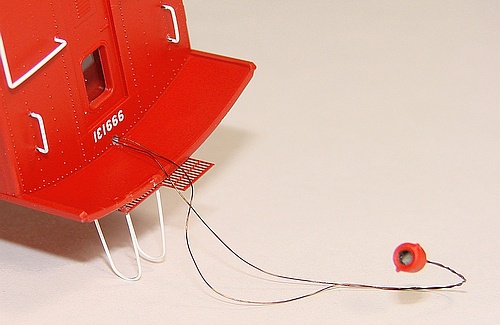

I shortened Detail Associates

1014 "Canadian Back-up Light"

parts (left) and drilled them out

(center) to house the tiny red

LEDs. The transformer wire has

an insulated coating, allowing it

to be twisted without electrical

shorts. Red MV Lenses (right)

were added after painting.

1014 "Canadian Back-up Light"

parts (left) and drilled them out

(center) to house the tiny red

LEDs. The transformer wire has

an insulated coating, allowing it

to be twisted without electrical

shorts. Red MV Lenses (right)

were added after painting.

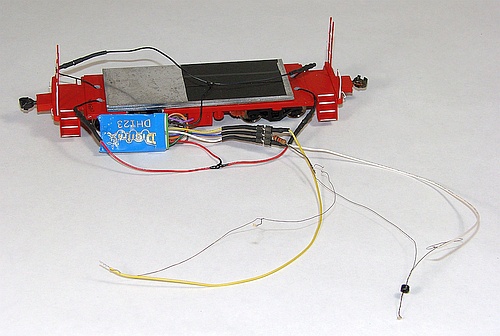

I've temporarily connected the wiring for testing.

The Digitrax DH123 decoder's functions are

used to control the red lights with DCC.

The Digitrax DH123 decoder's functions are

used to control the red lights with DCC.

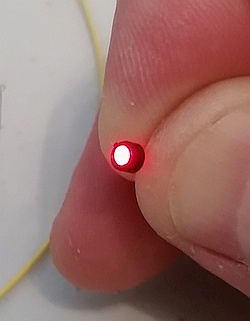

It works! A red LED

mounted in its housing and

lit up under DCC control.

mounted in its housing and

lit up under DCC control.

The housings and all other added details were brush-painted

red before installation. I drilled small holes through the end

walls for routing the transformer wires into the body. When the

waycar is viewed from above or the side, these holes are

hidden below the end roof eaves.

red before installation. I drilled small holes through the end

walls for routing the transformer wires into the body. When the

waycar is viewed from above or the side, these holes are

hidden below the end roof eaves.

For painting added details,

I blended a custom mix of

90% Polly-S Caboose Red

and 10% Polly-S ATSF Red

in an old Testors bottle.

I blended a custom mix of

90% Polly-S Caboose Red

and 10% Polly-S ATSF Red

in an old Testors bottle.

Completed light installation, using ACC adhesive.

Separating the car body from the floor took a bit of experimentation, but once solved it's not difficult to do (unfortunately, I didn't

take photos of this process). First, carefully pry loose the tops of the ladders from the end roof eaves - there is a weak glue joint

there. The ladders are pliable and can take some amount of bending. Next, from the bottom side, carefully wedge a flat-tip #17

Xacto blade into the seam between the sides of the body and the car floor. Work this along the sides until you're certain the seam

is loose (on my model, this seam appeared to be loose right out of the box). Finally, carefully fit the #17 blade between the end

ladder and brake stand, wedge it into the seam between the platform and the end wall, and gently twist the blade to break the

glue joint and lift the body up away from the platform. Do this at both ends, and the body should now be loose from the floor.

take photos of this process). First, carefully pry loose the tops of the ladders from the end roof eaves - there is a weak glue joint

there. The ladders are pliable and can take some amount of bending. Next, from the bottom side, carefully wedge a flat-tip #17

Xacto blade into the seam between the sides of the body and the car floor. Work this along the sides until you're certain the seam

is loose (on my model, this seam appeared to be loose right out of the box). Finally, carefully fit the #17 blade between the end

ladder and brake stand, wedge it into the seam between the platform and the end wall, and gently twist the blade to break the

glue joint and lift the body up away from the platform. Do this at both ends, and the body should now be loose from the floor.

Left: A view of the plug/receptacle connections for the trucks. I drilled

holes through the floor, large enough for the connectors to pass

through in case the trucks ever need to be removed.

I modified the Athearn truck mounting ring, and the Centralia bolster

system, to ensure the couplers sit at the correct height. I used the

stock couplers - they're permanently installed in the centersill and

I didn't want to risk damaging it.

Note: the Athearn 4593 trucks come with an axle generator on one

truck, but it's on the wrong (outer) axle and it's partly molded into the

truck sideframe! To solve this, I bought two pairs of trucks and used

the two non-generator trucks (the two generator trucks can be used

for a future project).

I installed a brass generator from American Scale Models on the

inner axle at the cupola end. However, it stands up quite high and

interfered with the car floor. I cut out an area of the floor (the white

plastic visible here) to clear the generator. This was later painted

black to disguise it.

Below: The completed axle generator sits up into the

carbody per the prototype. Also, I painted the sealed

window frames aluminum to match the prototype.

holes through the floor, large enough for the connectors to pass

through in case the trucks ever need to be removed.

I modified the Athearn truck mounting ring, and the Centralia bolster

system, to ensure the couplers sit at the correct height. I used the

stock couplers - they're permanently installed in the centersill and

I didn't want to risk damaging it.

Note: the Athearn 4593 trucks come with an axle generator on one

truck, but it's on the wrong (outer) axle and it's partly molded into the

truck sideframe! To solve this, I bought two pairs of trucks and used

the two non-generator trucks (the two generator trucks can be used

for a future project).

I installed a brass generator from American Scale Models on the

inner axle at the cupola end. However, it stands up quite high and

interfered with the car floor. I cut out an area of the floor (the white

plastic visible here) to clear the generator. This was later painted

black to disguise it.

Below: The completed axle generator sits up into the

carbody per the prototype. Also, I painted the sealed

window frames aluminum to match the prototype.

Below: The complete wiring installation. I tack-glued the

transformer wires from the end lights into the upper

corners of the body and soldered on short lengths of

standard wire with connector pins. These are plugged

into receptacles soldered to the decoder's wiring harness,

allowing the car body to be "unplugged" from the floor.

transformer wires from the end lights into the upper

corners of the body and soldered on short lengths of

standard wire with connector pins. These are plugged

into receptacles soldered to the decoder's wiring harness,

allowing the car body to be "unplugged" from the floor.

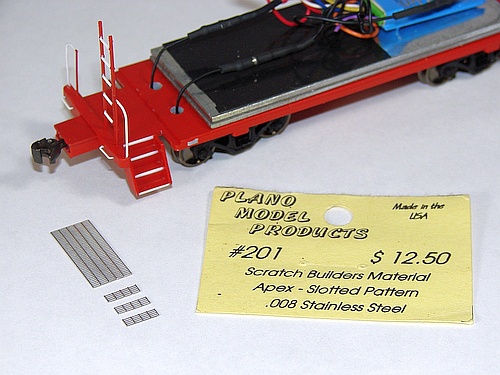

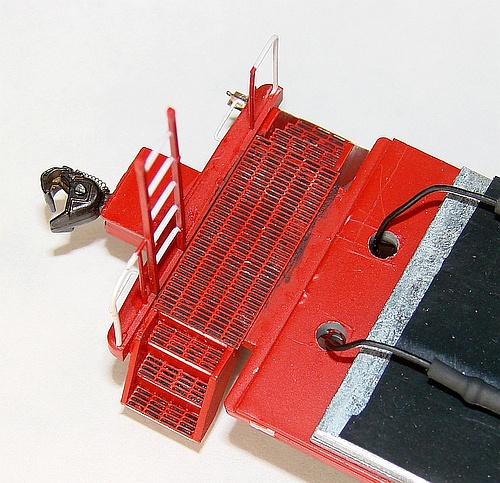

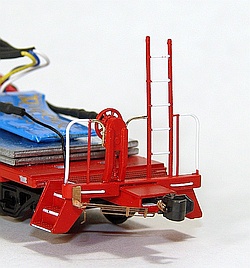

Below: To simulate treadway grating on the end platforms and

steps, I cut pieces to size from a sheet of Plano Models

201 Apex Slotted-Pattern stainless steel material, and painted

them red before installation. I painted the stock platforms flat black

before ACC gluing on the gratings. Some of the red paint chipped

off, which gives these a prototypical worn look. This method is an

acceptable compromise to a full "see-through look". I chose to not

open the platforms and steps as I was concerned about

compromising mechanical integrity of the platforms.

steps, I cut pieces to size from a sheet of Plano Models

201 Apex Slotted-Pattern stainless steel material, and painted

them red before installation. I painted the stock platforms flat black

before ACC gluing on the gratings. Some of the red paint chipped

off, which gives these a prototypical worn look. This method is an

acceptable compromise to a full "see-through look". I chose to not

open the platforms and steps as I was concerned about

compromising mechanical integrity of the platforms.

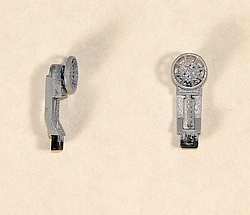

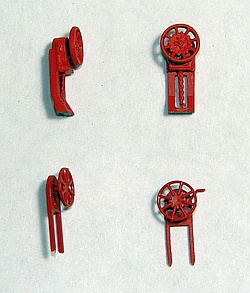

I replaced the stock brake stands and wheels with parts

from an Athearn "blue box" caboose. Compare the "beefier"

Athearn parts (top) to the undersized Centralia parts (bottom).

from an Athearn "blue box" caboose. Compare the "beefier"

Athearn parts (top) to the undersized Centralia parts (bottom).

Plano coupler cut bars were modified for the ends.

Bits of brass wire were shaped to complete the railings.

Bits of brass wire were shaped to complete the railings.

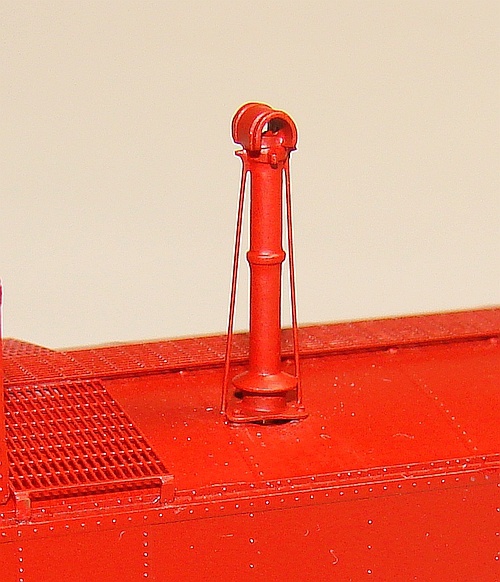

Below: a brass smoke jack from American Scale Models, shortened

below the top cap, replaced the stock part. Wire supports were added.

below the top cap, replaced the stock part. Wire supports were added.

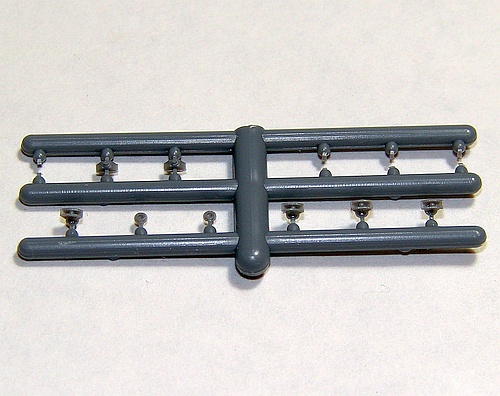

Below: Cannon & Co. 2052 step lights were assembled on the sprue.

Right: I installed these at the corners of the caboose and then painted

them red. Also, this is a good photo of the yellow-painted sloped vent

added above the "n" and "t" in the yellow herald (discussed below).

Right: I installed these at the corners of the caboose and then painted

them red. Also, this is a good photo of the yellow-painted sloped vent

added above the "n" and "t" in the yellow herald (discussed below).

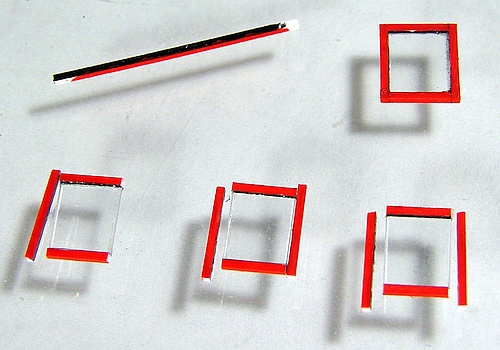

The Centralia model has sealed windows on the front and rear of the cupola - this is incorrect for Ce-1 waycars. I replicated the "box frame"

look of these windows using small styrene strip painted black on the inner surface and red on the adjacent and opposite surfaces. The fourth

surface was left bare for gluing to the cupola. 0.015" thick clear styrene was cut to size and "framed" with the painted styrene strip using

clear canopy glue. On the cupola, the sealed window frames were sanded smooth and the rounded corners cut away in preparation for

attaching the new windows. Once installed, the "glass" was temporarily covered with painters tape during the weathering process.

look of these windows using small styrene strip painted black on the inner surface and red on the adjacent and opposite surfaces. The fourth

surface was left bare for gluing to the cupola. 0.015" thick clear styrene was cut to size and "framed" with the painted styrene strip using

clear canopy glue. On the cupola, the sealed window frames were sanded smooth and the rounded corners cut away in preparation for

attaching the new windows. Once installed, the "glass" was temporarily covered with painters tape during the weathering process.

The Centralia model is missing the sloped vents found on both

sides of Ce-1 waycars. Left: a red-painted vent is visible above and

left of the yellow herald. A yellow-painted vent was installed on the

opposite side in the yellow herald above the "n" and "t". I shaped

these vents from 0.040" thick styrene and brush painted. A small

patch of the stock paint was scraped away to expose the body

plastic, where the new vents were attached with styrene cement.

sides of Ce-1 waycars. Left: a red-painted vent is visible above and

left of the yellow herald. A yellow-painted vent was installed on the

opposite side in the yellow herald above the "n" and "t". I shaped

these vents from 0.040" thick styrene and brush painted. A small

patch of the stock paint was scraped away to expose the body

plastic, where the new vents were attached with styrene cement.

Right: On my model, the stock window "glass" had come loose from

the side windows. I discarded those and replaced them with 0.015"

clear styrene cut to match the sealed window shape. These are

attached with clear canopy cement, resulting in flush-mounted

"glass" that is more prototypical.

Final assembly: The body-mounted light plugs were connected to

the floor-mounted receptacles and a final DCC test of the red end

lights performed. To mate the body to the floor, the end ladders

were gently held clear of the roof eaves as the body was pressed

back down onto the floor. I chose not to glue the body in place, as it

holds quite well with friction alone and I want to have easy access

to the interior in case the electronics need servicing in the future.

the side windows. I discarded those and replaced them with 0.015"

clear styrene cut to match the sealed window shape. These are

attached with clear canopy cement, resulting in flush-mounted

"glass" that is more prototypical.

Final assembly: The body-mounted light plugs were connected to

the floor-mounted receptacles and a final DCC test of the red end

lights performed. To mate the body to the floor, the end ladders

were gently held clear of the roof eaves as the body was pressed

back down onto the floor. I chose not to glue the body in place, as it

holds quite well with friction alone and I want to have easy access

to the interior in case the electronics need servicing in the future.

Left: To simulate flaking red paint on the roof exposing underlying

metal (a common sight on ATSF waycars), a sea sponge from the

art supply store was used to gently "dry-dab" on primer gray paint

resulting in tiny specs.

Next, roof brown paint was dry-brushed on the end surfaces of steps

and sills, along with the battery box ends and also the trucks. This

was followed by dry-brushed dust colored paint to simulate the

typical road grime that accumulates around these low areas (see

the finished images at top of page).

Dry powder chalks were applied over the roof and sides, fixed in

place with Testors Dullcote spray. Wheels and couplers were

brush-painted roof brown.

metal (a common sight on ATSF waycars), a sea sponge from the

art supply store was used to gently "dry-dab" on primer gray paint

resulting in tiny specs.

Next, roof brown paint was dry-brushed on the end surfaces of steps

and sills, along with the battery box ends and also the trucks. This

was followed by dry-brushed dust colored paint to simulate the

typical road grime that accumulates around these low areas (see

the finished images at top of page).

Dry powder chalks were applied over the roof and sides, fixed in

place with Testors Dullcote spray. Wheels and couplers were

brush-painted roof brown.

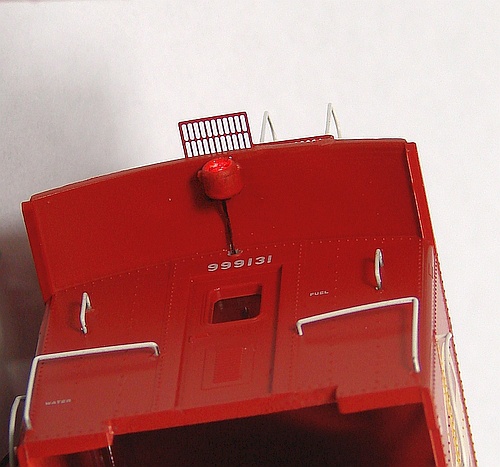

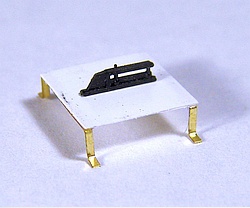

Below: The antenna is a Detail Associates 1803 Sinclair type on a

scratch-built platform using brass strip and styrene sheet. Brass wire

simulates the antenna electrical cable. Also, a brass wire vent pipe

was added adjacent to the cupola.

scratch-built platform using brass strip and styrene sheet. Brass wire

simulates the antenna electrical cable. Also, a brass wire vent pipe

was added adjacent to the cupola.

Right: I added wire sunshade supports per the prototype. After

weathering, A-Line 29202 short window wipers were installed

on the cupola end window frames. Details Associates 2312 straight

cab air deflectors, their inner edges painted red, were installed

adjacent to the cupola side windows using clear canopy glue.

weathering, A-Line 29202 short window wipers were installed

on the cupola end window frames. Details Associates 2312 straight

cab air deflectors, their inner edges painted red, were installed

adjacent to the cupola side windows using clear canopy glue.

-- About

-- Contact

-- Diesels

-- Links

Right: ATSF 999139 is typical of

the Ce-1 waycar class I modeled.

the Ce-1 waycar class I modeled.

entire website copyright Gregg Fuhriman

created with CoffeeCup Visual Site Designer

created with CoffeeCup Visual Site Designer

-- Layouts

-- Modules

-- Signalling